3200cc Mighty Mouse

Page 3

Crank work includes welding up the rod journal holes and redrilling and reshaping them for increased oil flow and better lubrication properties with new crank rotation. The flywheel hub is removed and a set of chrome moly woodruff keys are inserted, and the flywheel bolt holes are enlarged from 3/8-in. to 7/16-inch. After the hub is pressed on, two threaded dowels are installed for added strength.

We decided to retain and modify the stock rods but, if the budget allows, a set of stronger aftermarket rods should be used. Rods get shot peened, polished, wrist pin bushings installed and ARP heavy-duty rod bolts installed. This was done to convert the rod/piston setup over to a floating pin design as opposed to the stock press-fit style. Next, the crank is machined and reworked for extra strength, and then it gets straightened, reground and nitrated.

Above left, Cima 94mm pistons and cylinders are used on this engine, as opposed to the stock version which is not of the full-floating design.

Above center, is a comparison between the Cima barrel and the stock Corvair cylinder. The required modifications to the Cima cylinder are evident due to the different design alone. But it's worth it since they are bigger and much stronger than the stock GM component.

Above right, the owner of this motor opted to use his stock rods, but they were shot peened, clearanced, polished, and wrist pin bushings were installed, in addition to using ARP HD rod bolts.

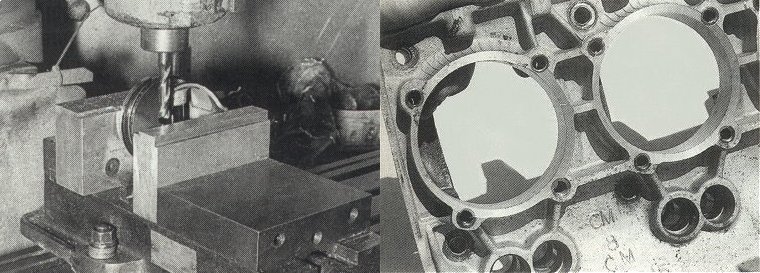

Above left, the process of notching the piston skirt, which is required to provide the needed clearance as the motor rotates and the piston reaches bottom-dead-center position.

At right, the case thru-bolts are reamed out to allow for larger diameter ARP case studs, and steel inserts are installed for the 10mm head studs and, finally, the case gets bored oversize for the aftermarket cylinders.